Heat Exchanger (for high temperature)

Safety & High Efficiency are achieved

Conventional high-temperature heat exchangers have been cooled by installing a throwing-in type cooling coil in the "heat medium tank". When the heat medium temperature is close to the set value, the amount of cooling water decreases and boils in the coil cause damages piping system. In case when fluorinated Inert liquid & Cooling Water accidentally mixed & the heat medium boils around Heater, it will be generating extremely harmful substances.

Therefore the system was used to be suitable only for use in a very narrow temperature range due to the characteristics of the bare winding cooling coil.

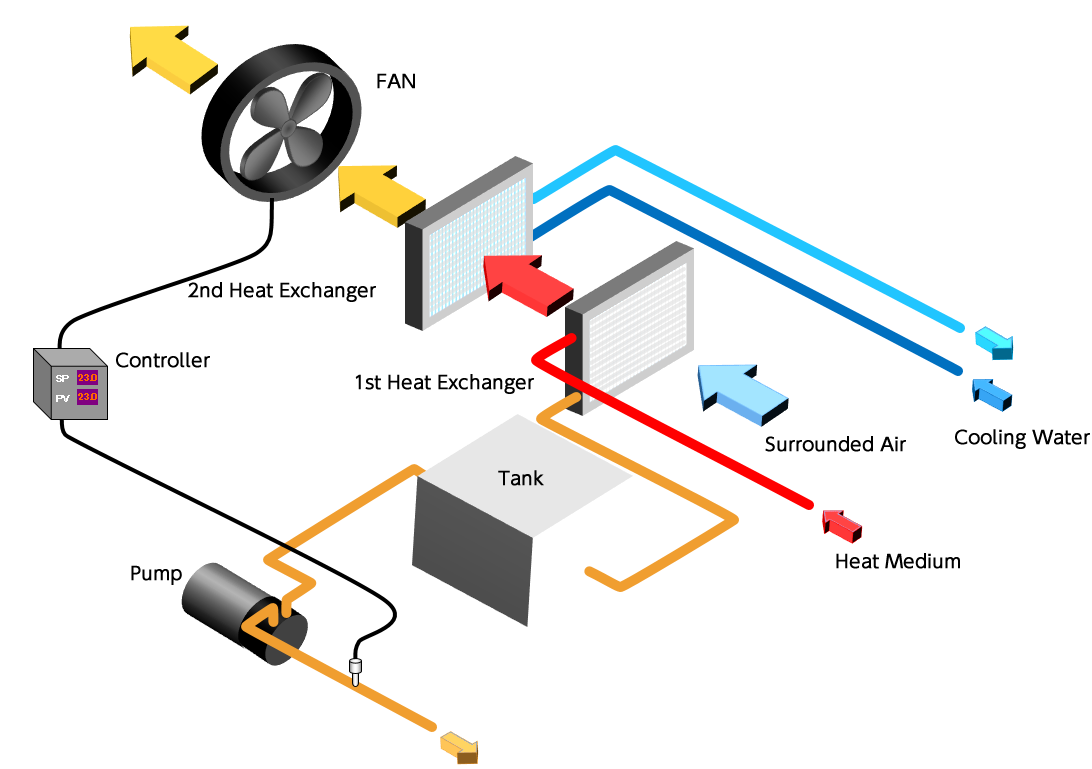

This system uses two heat exchangers as shown in the flow chart below to solve these problems.

The first heat exchanger cools the high-temperature heat medium with air, and the second heat exchanger cools the air with cooling water.

In this way, we achieved safe, accurate cooling & temp controlling by using two heat exchangers effectively.

Performance SPEC.

External Dimension:

400mm(W) x 1100mm(D) x 1600mm(H)

Main Material

Steel

Power Source

3 phases, 200V, 50/60Hz, 16.3A

Controllable Temp. Range

50 degrees C to 170 degrees C

Temp. Command / Setting resolution

1 degree C

System Flow